株洲冶炼集团股份有限公司

2024年-2025年锌供应链尽责管理年度报告

我们认识到,在受冲突影响和高风险区域从事矿产资源开采、交易、处理、出口等经营活动可能产生重大的社会和环境风险,并有尊重人权、不助长冲突,消除和管控相关风险的责任。公司秉持负责任、尊重、诚信的核心价值观,以一个评估周期为界编制发布一次本报告。通过展示和推进有效的管理持续增强对供应链的管理能力,以树立负责任的企业形象。同时,向供应商沟通明确的行为准则,强化其尽责管理意识和能力。

一、公司信息

公司名称:株洲冶炼集团股份有限公司

公司地址:湖南省株洲市天元区衡山东路12号

使用原料:锌精矿、锌焙砂、氧化锌、锌锭

主要产品:锌锭、热镀锌

LME注册品牌:TORCH III SHG

评估周期:2024年10月1日-2025年9月30日

二、依据标准

公司遵循以下标准实施矿产物供应链尽责管理:

1)《中国矿产供应链尽责管理指南》(第二版),简称《中国指南》 ;

2)参考《经济发展与合作组织关于来自受冲突影响和高风险区域的矿产的负责任供应链尽责调查指南》(第三版)——简称OECD指南 ;

三、供应链尽责管理实践

株冶集团自开展矿产供应链尽责管理工作以来,遵照我国矿产供应链尽责管理领域相关法规要求,并遵守矿源地所在国相应法规,逐步建立、完善锌矿产供应链尽责管理体系。先后按照《中国矿产供应链尽责管理指南》(第二版)、《经济发展与合作组织关于来自受冲突影响和高风险区域的矿产的负责任供应链尽责调查指南》(第三版)及其他相关标准和要求构建了公司锌矿产供应链尽责管理体系,制定了供应链政策及其他控制文件和透明度系统记录文件,逐步实现系统性、可追溯的供应链尽责管理。具体开展工作如下:

第一步 建立、完善锌矿产供应链尽责管理体系

1.锌矿产供应链尽责政策

为规避使用直接或间接为武装团体提供资金或使他们得益的冲突矿物及/或涉及在高风险和受冲突影响地区进行其他严重侵犯人权行为的冲突矿物,公司依据《中国矿产供应链尽责管理指南》(第二版)、《经济发展与合作组织关于来自受冲突影响和高风险区域的矿产的负责任供应链尽责调查指南》(第三版)及其他相关标准和要求制定了《株冶集团有色金属股份有限公司锌矿产供应链尽责政策》及其他制度文件,并向利益相关者(供应商、客户和员工等)广泛传播,同时于公司官网公布:https://zy.minmetals.com.cn/xwzx_7742/zzxw/202412/t20241217_306513.html。

2.公司管理体系架构与运行机制

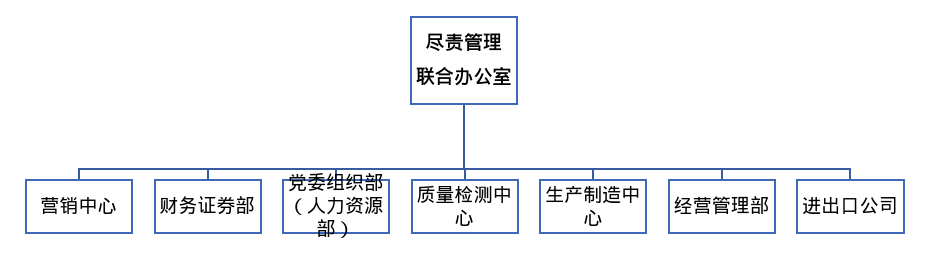

2.1组织结构。公司已构建由总经理领导,管理者代表全面负责的管理架构,实施锌矿产供应链尽责管理的策划、推进和改善,提供必要的资源支持。任命了管理者代表,组建了公司锌矿产供应链尽责管理委员会及跨部门的尽责管理联合办公室,并明确职责。日常工作在管理者代表领导下,由营销中心、进出口公司、财务证券部、企业管理部、党委组织部(人力资源部)、质量检测中心、生产制造中心及经营管理部等部门配合供应链管理联合办公室开展具体工作。 组织架构图如下:

为规范供应链尽责管理,公司锌供应链尽责管理联合办公室相继编制并发布了《锌矿产供应链尽责政策》《绩效考核管理办法》《供应商行为守则》《供应链尽责管理申诉处理办法》《尽责管理体系文件和记录控制程序》《矿产供应链风险管理程序》《年度培训计划》《风险管理计划管理程序》《内部评估程序》《尽责管理报告控制程序》《实地评估控制程序》及支持记录文件等30余份文件。

2.2公司按照年度培训计划组织对与公司锌供应链尽责管理相关的人员和部门及供应商开展锌供应链尽责管理专项培训,使其了解和掌握管理理念和工作方法。一年来,共开展培训8次,其中供应商培训2次,参加CCCMC2025年3月举办的内部评估员培训1次,公司内部培训5次。同时,积极参与供应商大会、相关方会议及供应商拜访等,定期收集国内外供应链尽责管理信息、资料、动态等,与相关人员共享学习,以提高公司尽责管理的整体能力。

3.供应链透明度管理。公司建立供应链控制和透明度系统(包含:供应链尽责管理程序、制度、结果及相应决策的内部记录等),用于识别我们所采购锌物料供应链中的上游参与者、原料来源国或地区以及运输路线等关键信息,为开展“警示信号审查”“风险识别与评估”及向关注的第三方传递负责任采购行为信息,同时也为后续工作提供基础信息,支持和改进体系运行。公司建立了质检系统(LIMIS系统),每个批次原料进厂信息、品质信息均能够在系统上进行记录、分析和展示,然后通过物料平衡计算,使其保持整体量处于合理范围内。进出口公司、营销中心、质量检测中心、生产制造中心分别按公司“供应商分类管理程序”所确定的职责和内容开展物料透明度管理工作,并配套《供应商合规监测表》等,实现含锌原料从:采购-进入公司-制成品-销售的全过程追溯。以此持续推进公司锌矿产供应链尽责管理的透明化、流程化和规范化。

4.记录保持。公司在《尽责管理体系文件和记录控制程序》中明确规定与锌矿产供应链尽责管理相关的所有记录原则上至少保存 5年,并在日常业务工作中得以执行。

第二步 与供应商合作

公司在建立锌矿产供应链尽责政策时明确了在原料采购过程中可能面临的各种风险,因而结合风险的可接受程度制定了针对性的缓解策略,且向供应商或相关给予展示和沟通。其次,我们制定了《供应商行为守则》,要求供应商签署供应链尽责管理声明和承诺,向供应商传达尽责管理相关责任;制定了《责任合同条款》,把公司锌原料采购的具体核心要求及要点列为合同内容,以契约形势给予遵守。同时,为进一步降低供应链上的风险或对识别出的风险改进绩效给予客观、有效之评价,公司建立《供应商识别问卷(KYS)》《管理政策、风险管理计划、报告征询意见表》,本报告期内陆续向供应商、客户发出管理政策、风险管理计划、报告征询意见表供其填写,供应商对公司供应链管理政策、风险缓解计划的内容、有效性、进展报告等都做了详细填写和回复,并持续收到供应商的反馈回复。

第三步 供应链风险识别与评估

1.公司策划并建立了锌矿产供应链尽责风险管理程序。以此为依据和程序,在此基础上日常工作以《锌矿产供应链尽责风险管理计划》《信息验证程序》《CAHRAs识别程序》等制度文件增强对进入公司的含锌原料进行风险识别和控制,也通过KYS调查表直接与供应商沟通、查询供应商公开信息等方式和渠道收集供应商相关合规性信息、原料信息、尽责管理信息等。

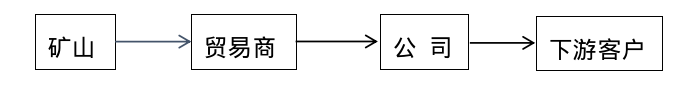

2.根据以上信息绘制供应链地图框架如下

3. 从武装冲突、人权、治理三个方面,使用如下资源或使用桌面研究和风险矩阵方法对矿产来源地进行风险评估,形成《警示信号识别清单》,使用工具主要包括:

a.《海德堡冲突晴雨表》,以国家或地区概览强度评分定义供应链冲突情况;

b.《联合国人类发展指数》, 以极高、高、中人权发展程度认定;

c.《世界银行全球治理指标》,以治理指数定义供应链治理情况;

d.《联合国制裁名单》/欧盟CAHRAs清单及参考《多德-弗兰克法案》,以名单内外涉及内容判定高低风险。

公司秉持高度的责任感,主动对供应商展开核查。我们重点关注供应商是否严格依照所在国法律要求,以及 EITI 倡议的相关规定,按时、足额地向政府缴纳税费,并按规范进行信息披露。参见:https://eiti.org/countries/

我们编制了《风险识别和评估报告》,最终结论为:公司大多数供应商位于低风险区域,运营规范,风险低。

第四步 风险管理与控制

公司制定了《锌矿产供应链尽责风险管理计划》,通过以下方式管理风险:

(1)在整个降低可衡量风险的过程中继续开展贸易;

(2)在不断降低可衡量风险的同时暂时中止贸易;

(3)在风险减缓失败或公司有理由认为风险减缓措施不可行或无法接受的情况下,终止与供货商的合作。

工作中我们通过《供应链追溯地图信息表》、《KYS调查表》、当面与供应商沟通等方式对供应链进行了解和调查,本评估年度内公司锌原料经追溯发现有来自国内的采购,也有部分原料经多级追溯发现来自刚果金、尼日利亚、秘鲁、玻利维亚、美国等13个国家。通过CAHRAs我们进一步了解到,这些风险主要由源国家发展受限或发展水平低造成,仅依靠公司单方面力量无法彻底解决,我们倡议必要时各利益相关方(包括供应链上下游企业、行业组织、相关国家政府等)协同合作,以更有效的方式根治风险源头。对此公司与相关供应商进行了很多有建设性的沟通和协商,讨论风险缓解措施及其可行性,但截止目前进展仍然缓慢,未及预期。

采掘业透明度倡议

我们深知透明度是建立合作的机会和基础,同时,尽责调查工作将有利于加强风险缓解和积极影响的创造,其结果是整个价值链的责任改善。公司秉持高度的责任感,主动对供应商展开核查。我们重点关注供应商是否严格依照所在国法律要求,以及 EITI 倡议的相关规定,按时、足额地向政府缴纳税费,并按规范进行信息披露。参见:https://eiti.org/countries/。

第五步 申诉机制与结果

为及时发现和处理供应链中可能存在的各类风险与隐患,保障利益相关方与公司的顺畅沟通,构建和谐互利的利益关系,公司建立和实施了《供应链尽责管理申诉机制》,并在公司网站(https://zy.minmetals.com.cn/xwzx_7742/zzxw/202412/t20241217_306516.html)及内部实体位置向公众公布,以收集各利益相关方意见或建议。本评估年度内经收集统计,没有收到各利益相关方的申述意见。因此,本报告期内收到供应商和利益相关的投诉事件为“零”。

第六步 对触发警示信号采购原料的管理

本评估周期内公司锌原料采购有83家一级供应商,其中矿源地位于国外的锌精矿供应商21家,矿源地位于国内的锌精矿供应商51家,国内锌锭供应商11家,涉及的国家包括中国、玻利维亚、秘鲁、刚果(金)等,主要为低风险国家,也有少部分来自高风险国家(刚果金)。经审查发现来自高风险国家的供应商矿山触发了公司锌矿产供应链尽责体系确定的一类警示信号。为此,针对其我们从以下几个方面开展了相关工作:一是加强对产销监管链或供应链追溯信息的进一步收集和验证。本着从源头识别、降低、控制风险的意愿,对于来自触发警示信号地区的原料公司强化了监管力度,通过网络、电话沟通等方式持续健全、完善供应链信息,并试图摸清楚、搞明白每一批次物料的详细信息,持续把公司尽责管理诉求和压力通过一级供应商向上游多级供应商持续传导;二是更进一步对触发警示信号原料的原产地信息按《中国矿产供应链尽责管理指南》(第二版)5.1.3.1及5.1.3.3条款12项条款要求,尽力持续作更进一步的信息收集和确认;第三,如有可能我们将逐步对所有国外采购的矿物收集其矿产原产地证、矿产的境外运输路线和运输方法、矿山开采量和开采方式等供应链追溯详尽信息,以期建立更完整的追溯系统。本评估周期内,公司逐步开始制定并实施上述措施,组建了实地评估小组,并制定了评估计划,但就目前公司自身能力及我们在行业内或供应链上的影响力还无法实质性推动相关工作开展。由于无法开展实地评估,公司已暂停高风险从刚果金采购锌精矿,同时我们与五矿商会取得联系,希望参加行业组织的联合实地评估。总之,我们期盼通过上述措施的实施,以加强对触发警示信号的采购原料进行管理,确保公司锌物料的采购不造成供应链政策中承诺的三种类型风险。

第七步 独立第三方评估与审核

可持续的锌矿产供应链尽责尽责管理公司不仅在内部持续推动,同时还接受外部独立第三方的审核评估,以满足利益相关方对公司锌矿产供应链尽责合规、透明的期望。截止目前,公司已先后累计多次接受第三方机构进行的外部评估,并通过评估,获得证书。本年度外部评估计划于2026年2月进行。同时,公司亦按《中国矿产供应链尽责管理指南》(第二版)、及公司锌矿产供应链尽责管理体系要求每年开展内部评估。本年度内部评估于2025年12月15日-16日开展,评估结束后编制了内部评估报告和改进项。以此循序渐进地从侧面更客观、公允、全面地对公司尽责管理体系的运行进行合理性、有效性评估,也反应公司尽责管理实践取得的成果。同时,提出改善意见和建议,实现持续改进,并由管理者代表向最高管理者报告情况。

第八步 尽责管理过程和结果的报告

公司每年完成上一年度的供应链尽责管理报告,并每年在公司网站公布一次。同时,供应链尽责管理相关信息及工作动态也适时在网站发布,为公众及利益相关方履行告知义务。公司于2024年12月19日至20日间接受了CCCMC委托的独立第三方评估机构中标合信(北京)认证有限公司的现场评估,结果为A级,摘要报告链接

https://www.cccmc.org.cn/kcxfzzx/zyzx/bg/ff808081964273600196601e28c70277.html。为持续健全、完善、履行公司对锌矿产供应链尽责的尽责管理义务,我们依据《中国矿产供应链尽责管理指南》(第二版)及公司锌矿产供应链尽责管理政策及程序之要求,积极、且多渠道地推进CAP项逐步关闭。

株冶集团在持续完善自身尽责管理的同时,更关注外部供应链合规的最新要求,我们不断加强与上下游企业的沟通、联系与交流,增进互信,积极参加行业会议、论坛及各类培训等,与相关方分享和报告供应链尽责管理的经验和进展,并呼吁锌行业相关方能共建更为持续、健康有效的锌矿产供应链尽责管理机制。

株洲冶炼集团股份有限公司

2025年11月25日

We recognize that engaging in mineral resource extraction, trading, processing, export, and other business activities in conflict-affected and high-risk areas may pose significant social and environmental risks. We also have the responsibility to respect human rights, not contribute to conflicts, and eliminate or control relevant risks. Adhering to the core values of responsibility, respect, and integrity, the Company prepares and issues this report once per assessment cycle. By demonstrating and advancing effective management, we continuously enhance our supply chain management capabilities to establish a responsible corporate image. Meanwhile, we communicate clear codes of conduct to suppliers and strengthen their awareness and capabilities in due diligence management.

The Company implements mineral supply chain due diligence management in accordance with the following standards:

Since launching mineral supply chain due diligence management, Zhuzhou Smelter Group has gradually established and improved its zinc mineral supply chain due diligence management system in compliance with relevant domestic regulations in the field of mineral supply chain due diligence and the corresponding laws of the countries where mineral sources are located. In accordance with the China Guidelines for Responsible Mineral Supply Chain Due Diligence (2nd Edition), the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (3rd Edition), and other relevant standards and requirements, the Company has built a zinc mineral supply chain due diligence management system, formulated supply chain policies, other control documents, and transparent systematic records. It has gradually realized systematic and traceable supply chain due diligence management. The specific work carried out is as follows:

To avoid the use of conflict minerals that directly or indirectly fund or benefit armed groups, or involve other serious human rights violations in high-risk and conflict-affected areas, the Company has formulated the Zinc Mineral Supply Chain Due Diligence Policy of Zhuzhou Smelter Group Co., Ltd. and other institutional documents in accordance with the China Guidelines for Responsible Mineral Supply Chain Due Diligence (2nd Edition), the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (3rd Edition), and other relevant standards and requirements. These documents have been widely disseminated to stakeholders (suppliers, customers, employees, etc.) and published on the Company’s official website: https://zy.minmetals.com.cn/xwzx_7742/zzxw/202412/t20241217_306513.html.

The Company has established a management structure led by the General Manager and fully managed by the Management Representative to plan, promote, and improve zinc mineral supply chain due diligence management, and provide necessary resource support. A Management Representative has been appointed, and a Zinc Mineral Supply Chain Due Diligence Management Committee and an inter-departmental Joint Office for Due Diligence Management have been established, with clear responsibilities. Under the leadership of the Management Representative, the daily work is carried out by the Joint Office for Supply Chain Management in collaboration with the Marketing Center, Import and Export Company, Finance and Securities Department, Enterprise Management Department, Party Committee Organization Department (Human Resources Department), Quality Inspection Center, Production and Manufacturing Center, and Operation Management Department.

To standardize supply chain due diligence management, the Joint Office for Zinc Supply Chain Due Diligence Management of the Company has successively formulated and issued more than 30 documents, including the Zinc Mineral Supply Chain Due Diligence Policy, Performance Appraisal Management Measures, Supplier Code of Conduct, Supply Chain Due Diligence Appeal Handling Measures, Due Diligence Management System Document and Record Control Procedure, Mineral Supply Chain Risk Management Procedure, Annual Training Plan, Risk Management Plan Control Procedure, Internal Assessment Procedure, Due Diligence Management Report Control Procedure, On-Site Assessment Control Procedure, and supporting record documents.

In accordance with the annual training plan, the Company organizes special training on zinc supply chain due diligence management for personnel, departments, and suppliers involved in the Company’s zinc supply chain due diligence management, to help them understand and master management concepts and working methods. Over the past year, a total of 8 training sessions have been conducted, including 2 sessions for suppliers, 1 session of internal assessor training organized by CCCMC in March 2025, and 5 internal training sessions of the Company. At the same time, the Company actively participates in supplier conferences, stakeholder meetings, and supplier visits, regularly collects domestic and international information, materials, and trends related to supply chain due diligence management, and shares and learns with relevant personnel to improve the overall due diligence management capabilities of the Company.

The Company has established a supply chain control and transparency system (including internal records of supply chain due diligence management procedures, systems, results, and corresponding decisions) to identify key information such as upstream participants, mineral source countries/regions, and transportation routes in the supply chain of zinc materials purchased by the Company. This system supports the conduct of "warning signal review", "risk identification and assessment", and the transmission of responsible procurement information to concerned third parties. It also provides basic information for subsequent work to support and improve the operation of the system.

The Company has established a quality inspection system (LIMIS system), where information on incoming materials (per batch) and quality information can be recorded, analyzed, and displayed on the system. Then, through material balance calculation, the overall quantity is maintained within a reasonable range. The Import and Export Company, Marketing Center, Quality Inspection Center, and Production and Manufacturing Center respectively carry out material transparency management in accordance with the responsibilities and contents specified in the Company’s Supplier Classification Management Procedure, and are supported by documents such as the Supplier Compliance Monitoring Form, to realize the whole-process traceability of zinc-containing raw materials from procurement, entry into the Company, processing into finished products, to sales. Through this, the Company continuously promotes the transparency, processization, and standardization of zinc mineral supply chain due diligence management.

In the Due Diligence Management System Document and Record Control Procedure, the Company clearly stipulates that all records related to zinc mineral supply chain due diligence management shall be retained for at least 5 years in principle, and this requirement is implemented in daily business operations.

When formulating the zinc mineral supply chain due diligence policy, the Company identified various risks that may be faced in the raw material procurement process. Therefore, it has formulated targeted mitigation strategies based on the acceptability of risks, and demonstrated and communicated these strategies to suppliers or relevant parties.

Secondly, the Company has formulated the Supplier Code of Conduct, requiring suppliers to sign supply chain due diligence statements and commitments to convey due diligence management responsibilities to suppliers; it has also formulated the Responsible Contract Terms, incorporating the specific core requirements and key points of the Company’s zinc raw material procurement into contract contents to ensure compliance through contractual agreements.

Meanwhile, to further reduce risks in the supply chain or objectively and effectively evaluate the performance improvement of identified risks, the Company has established the Supplier Identification Questionnaire (KYS) and Management Policy, Risk Management Plan, and Report Consultation Form. During the reporting period, the Company has successively sent the management policy, risk management plan, and report consultation form to suppliers and customers for completion. Suppliers have provided detailed responses and feedback on the content, effectiveness, and progress report of the Company’s supply chain management policy and risk mitigation plan, and the Company continues to receive feedback from suppliers.

The Company has planned and established a zinc mineral supply chain due diligence risk management procedure. Based on this procedure, daily work uses institutional documents such as the Zinc Mineral Supply Chain Due Diligence Risk Management Plan, Information Verification Procedure, and CAHRAs Identification Procedure to enhance risk identification and control of zinc-containing raw materials entering the Company. It also collects suppliers’ relevant compliance information, raw material information, and due diligence management information through channels such as direct communication with suppliers via KYS questionnaires and inquiry of suppliers’ public information.

Based on the above information, the supply chain map framework is drawn as follows:Mines → Traders → The Company → Downstream Customers

From the three aspects of armed conflict, human rights, and governance, the Company conducts risk assessment on mineral source areas using the following resources, desktop research, and risk matrix methods to form the Warning Signal Identification List. The main tools used include:a. Heidelberg Conflict Barometer: Defines the conflict situation of the supply chain based on the intensity score of country/region overview;b. UN Human Development Index: Classifies human rights development levels as very high, high, or medium;c. World Bank Governance Indicators: Defines the governance situation of the supply chain based on governance indices;d. UN Sanctions List/EU CAHRAs List, and with reference to the Dodd-Frank Act: Determines high or low risks based on whether the content is included in the lists.

The Company adheres to a high sense of responsibility and proactively conducts inspections on suppliers. We focus on whether suppliers pay taxes and fees to the government in a timely and full manner in accordance with the legal requirements of the countries where they are located and the relevant provisions of the EITI initiative, and disclose information in a standardized manner. See: https://eiti.org/countries/.

The Company has prepared the Risk Identification and Assessment Report, with the final conclusion that most of the Company’s suppliers are located in low-risk areas, operate in a standardized manner, and pose low risks.

The Company has formulated the Zinc Mineral Supply Chain Due Diligence Risk Management Plan and manages risks through the following methods:

In daily work, the Company understands and investigates the supply chain through methods such as the Supply Chain Traceability Map Information Form, KYS Questionnaire, and face-to-face communication with suppliers. During the assessment year, the traceability of the Company’s zinc raw materials shows that some materials are procured domestically, and some materials are traced through multiple levels to 13 countries including the Democratic Republic of the Congo (DRC), Nigeria, Peru, Bolivia, and the United States.

Through CAHRAs, we further understand that these risks are mainly caused by the limited development or low development level of the source countries, and cannot be completely resolved by the Company alone. We advocate that when necessary, all stakeholders (including upstream and downstream enterprises in the supply chain, industry organizations, and governments of relevant countries) should cooperate to address the root causes of risks in a more effective manner.

The Company has conducted many constructive communications and consultations with relevant suppliers to discuss risk mitigation measures and their feasibility, but progress has been slow so far and has not met expectations.

We are well aware that transparency is the foundation and opportunity for establishing cooperation. At the same time, due diligence work will help strengthen risk mitigation and the creation of positive impacts, resulting in improved responsibility throughout the value chain. The Company adheres to a high sense of responsibility and proactively conducts inspections on suppliers. We focus on whether suppliers pay taxes and fees to the government in a timely and full manner in accordance with the legal requirements of the countries where they are located and the relevant provisions of the EITI initiative, and disclose information in a standardized manner. See: https://eiti.org/countries/.

To promptly identify and address various potential risks and hidden dangers in the supply chain, ensure smooth communication between stakeholders and the Company, and build a harmonious and mutually beneficial stakeholder relationship, the Company has established and implemented the Supply Chain Due Diligence Appeal Mechanism. This mechanism has been published to the public on the Company’s official website (https://zy.minmetals.com.cn/xwzx_7742/zzxw/202412/t20241217_306516.html) and at internal physical locations to collect opinions or suggestions from all stakeholders.

During the assessment year, statistics show that no appeal opinions were received from any stakeholders. Therefore, the number of complaints from suppliers and stakeholders during the reporting period is "zero".

During the assessment cycle, the Company has 83 first-tier suppliers for zinc raw material procurement, including 21 zinc concentrate suppliers with mineral sources overseas, 51 zinc concentrate suppliers with mineral sources in China, and 11 domestic zinc ingot suppliers. The involved countries include China, Bolivia, Peru, the Democratic Republic of the Congo (DRC), etc., mostly low-risk countries, with a small number from high-risk countries (the DRC).

Reviews show that the mines of suppliers from high-risk countries have triggered Class I warning signals defined in the Company’s zinc mineral supply chain due diligence system. To address this, the Company has carried out the following work:

During the assessment cycle, the Company has gradually formulated and implemented the above measures, established an on-site assessment team, and formulated an assessment plan. However, due to the current capabilities of the Company and its influence in the industry or supply chain, it is unable to substantially promote the implementation of relevant work. Since on-site assessments cannot be conducted, the Company has suspended the procurement of zinc concentrate from high-risk areas in the DRC. At the same time, the Company has contacted the CCCMC (China Chamber of Commerce of Metals, Minerals & Chemicals Importers & Exporters) to participate in joint on-site assessments organized by industry organizations.

In short, the Company expects to strengthen the management of procured raw materials triggering warning signals through the implementation of the above measures, ensuring that the procurement of zinc materials by the Company does not cause the three types of risks committed in the supply chain policy.

The Company not only continuously promotes sustainable zinc mineral supply chain due diligence management internally but also accepts external independent third-party audits and assessments to meet the expectations of stakeholders for the compliance and transparency of the Company’s zinc mineral supply chain due diligence. Up to now, the Company has received external assessments by third-party institutions for multiple times, passed the assessments, and obtained certificates.

The external assessment for this year is scheduled to be conducted in February 2026. At the same time, in accordance with the requirements of the China Guidelines for Responsible Mineral Supply Chain Due Diligence (2nd Edition) and the Company’s zinc mineral supply chain due diligence management system, the Company conducts an internal assessment every year. The internal assessment for this year was carried out from December 15 to 16, 2025, and an internal assessment report and improvement items were prepared after the assessment.

Through this, the Company gradually conducts a more objective, fair, and comprehensive assessment of the rationality and effectiveness of the operation of its due diligence management system from an external perspective, reflects the achievements of the Company’s due diligence management practices, and puts forward improvement opinions and suggestions to achieve continuous improvement. The Management Representative reports the situation to the top management.

The Company completes the annual supply chain due diligence management report for the previous year and publishes it on the Company’s official website once a year. At the same time, information and work updates related to supply chain due diligence management are released on the website in a timely manner to fulfill the obligation of informing the public and stakeholders.

From December 19 to 20, 2024, the Company received an on-site assessment by Zhongbiao Hexin (Beijing) Certification Co., Ltd., an independent third-party assessment institution entrusted by the CCCMC, and obtained a Grade A result. The link to the summary report is: https://www.cccmc.org.cn/kcxfzzx/zyzx/bg/ff808081964273600196601e28c70277.html.

To continuously improve, perfect, and fulfill the Company’s due diligence management obligations for the zinc mineral supply chain, the Company actively promotes the gradual closure of Corrective Action Plan (CAP) items through multiple channels in accordance with the requirements of the China Guidelines for Responsible Mineral Supply Chain Due Diligence (2nd Edition) and the Company’s zinc mineral supply chain due diligence management policies and procedures.

While continuously improving its own due diligence management, Zhuzhou Smelter Group pays more attention to the latest requirements for external supply chain compliance. It continuously strengthens communication, contact, and exchanges with upstream and downstream enterprises to enhance mutual trust, actively participates in industry conferences, forums, and various training sessions, shares and reports experiences and progress in supply chain due diligence management with relevant parties, and calls on relevant parties in the zinc industry to jointly build a more sustainable, healthy, and effective zinc mineral supply chain due diligence management mechanism.

Zhuzhou Smelter Group Co., Ltd.

November 25, 2025